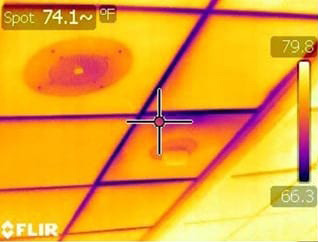

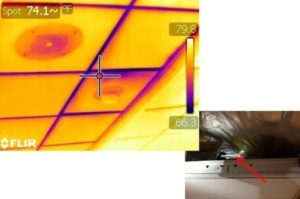

We were testing chilled beam operation using an infrared camera. With this handy instrument pointed at the ceiling, we could spot quickly, among several dozen chilled beams, whether they were going into heating or cooling mode as commanded during the functional performance test. While performing the inspection, we noticed particularly cold spots in the ceiling grid. What was going on above the ceiling tiles that could cause 66°F surface temperature?

After fetching a ladder and popping a tile, we discovered a supply air duct connection that was NOT fully connected. A sizeable opening in the ductwork was allowing cold air to pour into the plenum. A simple patch would go on to prevent this issue from causing further loss of cooling energy and fan electricity efficiency, lack of sufficient supply to the space, and potential, unwanted condensation. Without the infrared picture, this would probably have been detected AFTER a water stain became visible on the ceiling tile.

Sometimes in the field, with so many system components present, it is easy to focus on just the task at hand. However, keeping eyes open and allowing time to think allows issues with other systems, including systems that are “complete”, to reveal themselves.

Pro Tip: Whenever you see a stain on your ceiling tiles, inspect the plenum for the problem.